Ever wondered what CRI means? Do you need to know how light and color temperatures are measured? We have all the information you need!

Color Rendering Index CRI

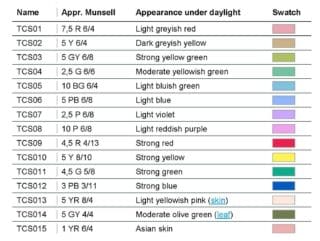

The Colour Rendering Index (CRI) is a measure of how faithfully a test light source can render a set of 15 defined colours when compared to a natural light source. The more balanced the rendering results are, the higher the CRI will be. If all test colours render equal to a tungsten halogen lamp the CRI would be 100.

A typical entertainment RGB led lighting fixture (Chroma-Q® Color Block™) has a CRI of 67. The MSR575 lamp fitted into many of the professional entertainment moving lights have a CRI of 70. Such are the advances in control technology that the latest Chroma-Q RGBA fixture (Color Force™) has a CRI of 92.

Click link to view the colour rendering index.

Colour Temperature

In physics, a black body is a theoretical object without reflective properties. When it is heated, it emits visible wavelengths dependent on temperature. With increased temperature, it glows red, orange, yellow, white, and finally blue. Stated in Kelvin, the “Colour Temperature” is the absolute temperature required for the black body to radiate a certain colour.

Kelvin is an absolute measure of temperature. A single Kelvin (K) (not expressed with a degree symbol) has the same interval as degree Celsius, however 0K = -273.25°C.

Our eyes automatically compensate for colour temperature. A book page can look equally white in daylight at midday and in tungsten light in the evening. However, the same page can look blue in daylight or yellow in tungsten light when recording an image on camera without adjustment. To get an accurate rendition of what you experience in person, it is critical to adjust for the colour temperature of the ambient light. When using film, the adjustment is made by selecting the correct physical media.

In practical terms, cameras are set to either Daylight/Outside (approx. 5600K) or Tungsten/Inside (approx. 3200K). For white objects to appear white, it is important to light the objects with the appropriate lighting source. It is possible to adjust the colour temperature of a lighting source by using filters. A blue filter can be used to adjust a tungsten source to produce daylight. And a yellow filter can be used to adjust a daylight source to produce tungsten light. A wide range of colour correction filters exists to balance most common light sources to appear the same on camera.

Colour Perception of the Human Eye

The normal human eye has over 125 million light sensors, split between rods and cones at a ratio of approximately 20:1.

The rods are significantly more sensitive to intensity than the cones, but the rods only perceive light as shades of grey. Whilst they cannot determine colour information they respond best to the low frequency light at blue end of the spectrum. Therefore our eyes are most sensitive to intensity changes in blue light.

The cones in the human eye are sensitive to colour across the full visible spectrum, with the highest level of sensitivity around the green/yellow area. Therefore, our eyes are most sensitive to colour change in the green/yellow part of the spectrum.

The rods work best in low-light situations, and therefore, colour perception is reduced. The colour-sensitive cones work best in high-light situations.

IP Ratings and Outdoor Use

The International Standard IEC 60529 specifies the full testing procedure for degrees of protection provided by enclosures. Products are tested in accordance with the IEC 60529 testing procedures, and where manufacturers claim compliance to a specific IP rating, they are only confirming that the product has passed the relevant test. Suitability for any specific application is not claimed or inferred, and it is strongly recommended that users carry out their own tests to establish the suitability of a product to specific site environmental conditions.

As an example, part of the the IEC 60529 IP65 test procedure requires that a stream of water is sprayed from a 6.3mm diameter nozzle at 12.5 litre/min from all practical directions from 2.5m-3m for 3 minutes. Passing an IP65 test does not imply that a product is suitable for outdoor use in any weather.

In addition to particle and water ingress, other factors to consider when evaluating a product’s suitability for a specific application should be the daily and annual temperature range, humidity, UV exposure, and the colour of the fixture (a black fixture in direct sunlight will easily exceed specifications).

It is recommended that users check with manufacturers directly regarding the suitability of a product for each specific installation.

Light Measurement

Light measurement is complex. It is difficult to compare products when manufacturers provide performance in different formats. Wattage is the measure of how much electrical power a light source uses, not how bright it is. Lumen is the best measure to use for a true comparison of output.

The lumen is the measure of a light source’s luminous power as perceived by the human eye. Lumens describe how much light is emitted from a light source in total.

The foot-candle is the amount of light that actually falls on a given surface. The foot-candle is equal to one lumen per square foot. A typical office environment may be around 50 fc, warehouse around 15 fc.

Just like the foot-candle, the lux is the amount of light that actually falls on a given surface (one lumen per square metre). One foot-candle = 10.764 lux. A typical office environment may be around 500 lux, a warehouse around 150 lux.

It is important to understand that a light source spread over a large area will measure less foot-candle/lux than the same source focused on a small area. However, the lumens remain the same. When using lux or foot-candle charts, be careful to compare fixtures with similar beam angles and distances.

The candela is the power emitted by a light source in a particular direction as perceived by the human eye. A domestic candle emits light with a luminous intensity of roughly one candela.

Nits are equivalent to candela per square meter. Nits are often used by screen manufacturers to illustrate how bright a screen is.

When comparing products, it is important to use the measure relevant to the task at hand:

- Fixture output comparison – lumens

- Light levels at a given distance – foot candle or lux

- Screen brightness – nit

Because the light output of an LED fixture varies with temperature, the percentage of that variation (the smaller the better) is an indicator of the quality of that LED lighting fixture. When referring to light output measurement from an LED fixture, one must use hot lumens. Hot lumens are measured after the LED light fixture has reached thermal equilibrium. Normally, that should be the case after the fixture has been on at full for at least thirty minutes to two hours or more, depending on the size of the fixture (the other way is to measure the temperature of the heat sink of the fixtures and wait 10 minutes after the temperature has stopped climbing).

Light Efficacy

How efficient is my light source?

Lumens per Watt is the best way to measure the efficacy of a light source.

As a comparative guide:

Candle = 0.3lm/W

HPL+ tungsten halogen lamp = 14,900lm/575W = 26lm/W – 400hr

CP82 tungsten halogen lamp = 13,500lm/500W = 27lm/W – 150hr

MSR575 HR discharge lamp = 40,000lm/575W = 85lm/W – 1,000hr

Fluorescent T8 lamp = up to 100lm/W – 18,000hr

Luxeon Rebel LED 5,700K white at 350mA = 100lm/W – not quoted

Luxeon Rebel LED 5,700K white at 700mA = 80lm/W – 50,000hr L70

The design and cleanliness of all optical elements: lenses, coatings, filters and reflectors will factor in the efficacy of a lighting fixture. The efficacy of the power supply and electronics are also an important factor. The above information is ONLY provided as a guide to the actual lamp or light source.

Is my light source fit for purpose?

Additional consideration should also be given to the relevance of the light source in relation to purpose. For example, it is now recognised that full spectrum lighting improves driver reaction times and changing light sources from low CRI to high CRI can reduce accidents. Alternatively safety levels can be preserved with less power if high CRI sources are used for street lighting.

LED Colour Matching

In the manufacturing of semiconductor products, there is a variation of performance around the average values given in the manufacturers technical data sheets. For this reason, manufacturers bin the LED components for luminous flux, forward voltage and colour frequency. Specific bin LEDs are available for purchase at additional cost for applications where consistency across units is critical.

Some high quality fixture manufactures (Chroma-Q for example) have developed technology to adjust for variances in luminous flux and forward voltage between batches of LED. Regarding colour frequency, the human eye is most sensitive to colour frequency variance around the green/yellow (550nm) area and Chroma-Q LED fixtures are manufactured with the most tightly binned LEDs available (5nm) around this area. It should be noted that some people can still detect a slight variance within the 5Nm tolerance.

LED Performance Over Time

One of the strongest propositions of power Light Emitting Diodes (LEDs) is their long lumen maintenance – their ability to continue producing light output for many years of use, in contrast to most conventional light sources, which force users to go through repeated and frequent failure-and-replacement cycles.

LEDs experience a gradual reduction in light output during operation. This phenomenon is called light output degradation and may stem either from a reduction in the light-emitting efficiency of the LED chip or a reduction in the light transmission of the optical path within the LED package. However, noting that the light output of an LED tends to degrade gradually as the device is stressed, its efficacy may fall to an unacceptable level long before total failure occurs. Such a condition may be described as a lumen maintenance failure. An LED with a lamp life quoted as up to 50,000 hours L70, should expect that 50% of units will have less than 70% of their initial output.

Colour Mixing

It is unlikely that all colours in a colour mixing LED fixture will have equal usage. It is therefore likely that a colour mixing LED fixture will become less able to deliver consistently accurate mixed colours after significant usage.

50,000 hours is equivalent to 6 years usage at 24 hours a day, 7 days a week. In a typical production environment a fixture may be used around 3 hours a day, 6 days a week, which is less than 1,000 hours a year.

Many LED fixtures incorporate LED engines with a lamp life quoted as up to 50,000 hours L70. Other components inside the fixtures have significantly shorter anticipated life therefore lamp life should not be misinterpreted as a likely life of the product as a whole.

Continue Reading

Continue Reading

Conversion Factors

May 20, 2025

Discover the LumiNode Process Engine

May 20, 2025

Unveil the Power of Araneo

May 20, 2025